wholesale different shapes W75Cu25 tungsten copper alloy

wholesale different shapes W75Cu25 tungsten copper alloy

Description of W75Cu25 tungsten copper alloy

Tungsten copper alloy (Copper Tungsten Alloy, CuW, or WCu) is a pseudo-alloy of copper and tungsten. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The alloy combines the properties of both metals, resulting in a material that is heat-resistant, ablation-resistant, high thermal and electrical conductivity, and easy to machine. Parts are made from the WCu alloy by pressing the tungsten particles into a desired shape, sintering the compacted part, then infiltrating with molten copper. Sheets, rods and bars of the alloy are available as well.

Resistance welding electrode

It integrates such features of tungsten and copper as high temperature resistance, electrical arc ablation resistance, high proportion, good electrical and heat conductivity, being easy to cut and transpiration cooling. It also owns such advantages of tungsten as high hardness, melting point and adherence resistance. It is often used for projection welding and butt-welding electrode with wear and high temperature resistance.

Electric spark electrode

It is used for the electrode of mould made from tungsten steel and high-temperature and ultra hard alloy. The common electrode has high consumption and low rate. The high electrical ablation rate, low consumption ratio, precise electrode size and quality processing performance of Copper tungsten can ensure that the precision of the work piece is greatly enhanced.

High-voltage discharge tube electrode

When the high-voltage vacuum discharge tube is working, the temperature of contact material will rise to thousands degree centigrade within several tenths seconds. High ablation resistance, high toughness, good electrical and heat conductivity of Copper tungsten provide necessary conditions to stable operation of the discharge tube.

The information on website is only one part,Our factory accept custom-made,so please send me your drawing or tell me your request online

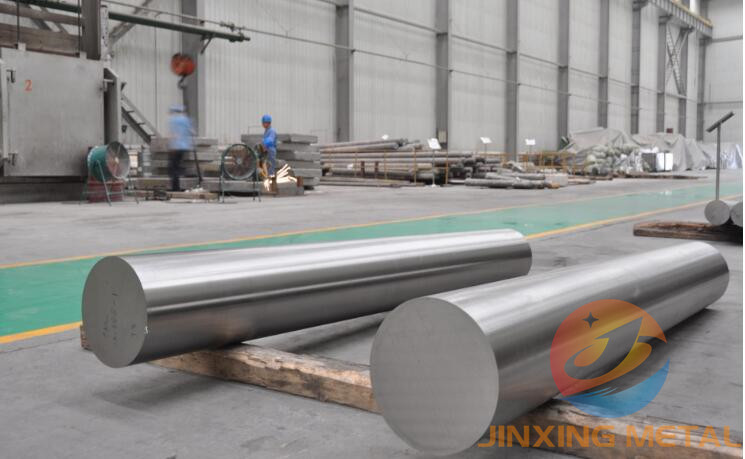

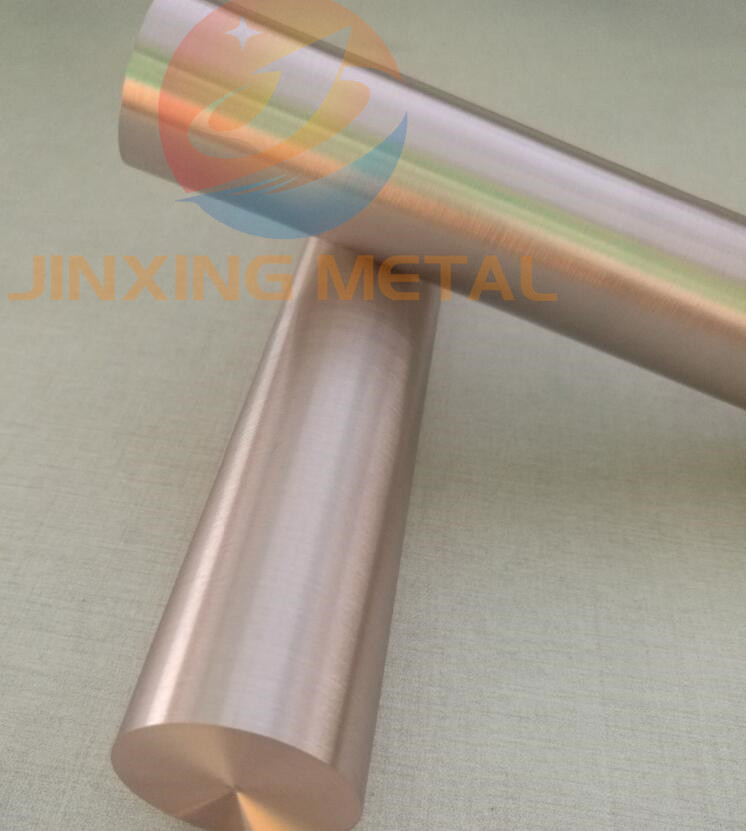

Pictures of our W75Cu25 tungsten copper alloy

Chemical Composition of our W75Cu25 tungsten copper alloy

|

Class |

Chemical Composition(Wt%) |

Density |

Hardness |

Resistance rate |

IACS |

Bending strength |

||

|

Cu |

Total Additives≤ |

W |

g/cm3≥ |

kgf/mm4≥ |

um.cm≤ |

%≥ |

MPa≥ |

|

|

W93Cu07 |

7±1.0 |

0.5 |

balance |

17.5 |

270 |

7.2 |

26 |

1190 |

|

W90Cu10 |

10±2.0 |

0.5 |

balance |

16.75 |

260 |

6.5 |

27 |

1160 |

|

W85Cu15 |

15±2.0 |

0.5 |

balance |

15.90 |

240 |

5.7 |

30 |

1080 |

|

W80Cu20 |

20±2.0 |

0.5 |

balance |

15.15 |

220 |

5.0 |

34 |

980 |

|

W75Cu25 |

25±2.0 |

0.5 |

balance |

14.50 |

195 |

4.5 |

38 |

885 |

|

W70Cu30 |

30±2.0 |

0.5 |

balance |

13.80 |

175 |

4.1 |

42 |

790 |

|

W65Cu45 |

0.545±2.0 |

0.5 |

balance |

13.30 |

155 |

3.9 |

44 |

650 |

|

W60Cu40 |

40±2.0 |

0.5 |

balance |

12.75 |

140 |

3.7 |

47 |

600 |

|

W55Cu45 |

45±2.0 |

0.5 |

balance |

12.30 |

125 |

3.5 |

49 |

565 |

|

W50Cu50 |

50±2.0 |

0.5 |

balance |

11.85 |

115 |

3.2 |

54 |

534 |

W75Cu25 tungsten copper alloy of Applications

Because of the high electrical conductivity and low consumption, Copper tungsten bars are widely used to make Grid siderod, Lead, Support, and Electrode for the Gas discharge lamp.