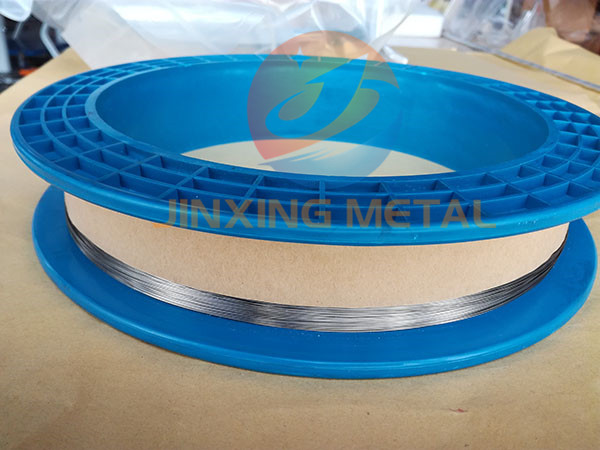

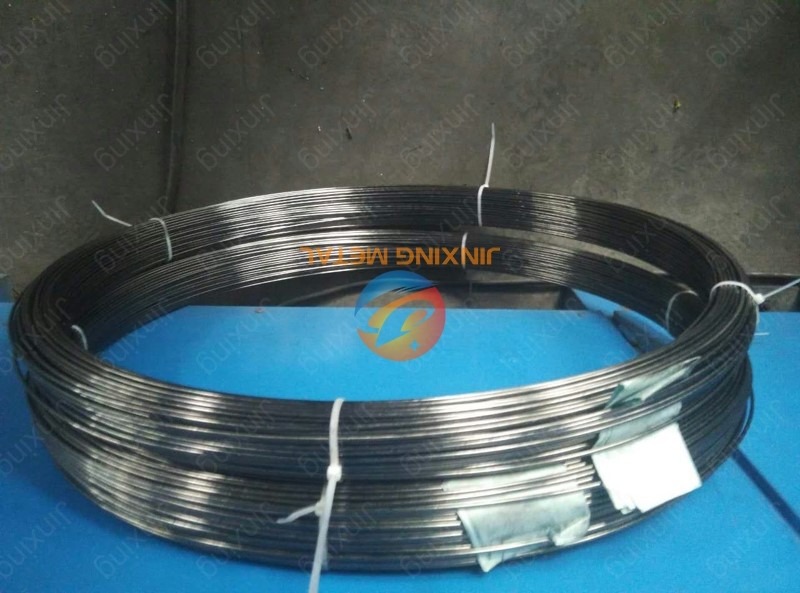

High quality molybdenum wire from JinXing Matmetals

• molybdenum wire is refers to the line cutting with a high-voltage electric field to move continuously to cut the workpiece by a molybdenum and other precious metals made of consumables, that WEDM workpiece when moving continuously fine metal wire called the electrode wire Called the electrode), which can be carried out on the workpiece pulse spark erosion erosion, cutting metal forming. Molybdenum wire according to the different materials there are many other uses are as follows

1. molybdenum wire is used for wire around the wire, stents, leads, heating elements, molybdenum foil tape, wire molybdenum wire applications – fast wire cutting machine tools, auto parts, such as spraying.

2. molybdenum wire is used for cutting a variety of non-ferrous metals, iron and steel and magnetic materials. That with the high strength, good discharge performance, high surface finish, cutting speed, long life and other characteristics.

|

Diameter, mm |

Diameter telorance, % |

Weight ( 200mm ), mg |

Length min, m |

|

0.015−0.03 |

− |

0.360−1.440 |

2000 |

|

0.03−0.1 |

1.440−16.00 |

1500 |

|

|

0.1−0.2 |

±0.5−±1.5 |

16.00−256 |

1000 |

|

0.2−0.4 |

300 |

||

|

0.4−0.7 |

±1.5−±2.5 |

− |

same as 200g |

|

0.7−1.8 |

±1.0−±2.0 |

same as 250g |

|

Mo |

C |

N |

O |

Fe |

Ni |

Si |

|

≥99.95 |

≤0.01 |

≤0.002 |

≤0.007 |

≤0.010 |

≤0.005 |

≤0.010 |

edm moly wire

• High melting point, Low density and Thermal coefficients

• Good thermal conductivity properties and Resistance of high-temperature

• High tensile strength and Low elongation

• Good stability and High precision of cutting

• High speed and Long stable time of processing

• Long lifetime and Non-poisonous

• Electric light source, Electrode

• Heating elements, High-temperature components

• Wire-electrode cutting

• Spraying for auto parts