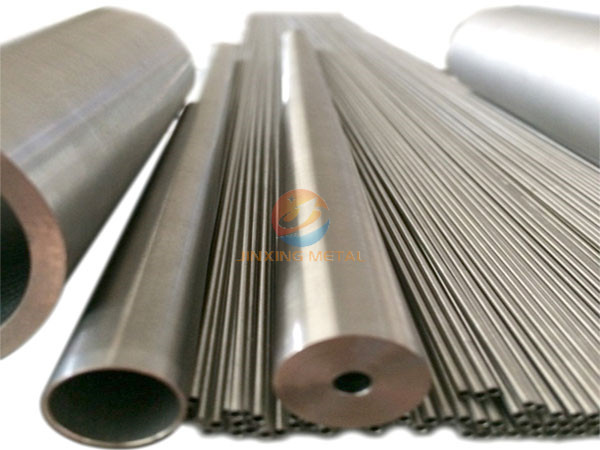

GR1 GR2 GR5 round titanium hollow bar price per kg

Medical Titanium Hollow Bar products are widely used: navigation, aerospace, Peducle screw, locking screw.vacuum salt making, automobile industry, medical and sports, papermaking textile industry, Material: Ti6AL4V ELI

Product Performance

1. Low density , high strength

2. High operating temperature , anti-corrosion

5. Low temperature resistance and no magnetic

6. Good skin compatibility

|

Standard |

ASTM B348, F67, F136 |

|

Material |

Gr1,Gr2, Gr3 Gr4,Gr5,Gr9 ,Gr12,6Al-4V ELI,Ti 3Al-2.5V |

|

Surface Treatment |

Polished, machined, peeled |

|

MOQ |

10 kgs |

|

Payment terms |

T/T or L/C at sight |

|

Diameter |

6.0-300mm |

|

Ti (Min) |

99.50% |

|

Technique |

Rolled , Forged |

|

Length |

equal or less than 6000mm |

|

Density |

4.506-4.516g/cm^3 |

|

Feature |

1)low density and high strength 2)excellent corrosion 3)good resistance to effect of that 4)excellent bearing to cryogenic property 5)nonmagnetic and non-toxic 6)good thermal properties 7)low modulus of elasticity |

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

bal |

|

grade |

Tensil strength(min) |

Yeild strength(min) |

Elongation(%) |

||

|

ksi |

MPa |

ksi |

MPa |

||

|

1 |

35 |

240 |

20 |

138 |

24 |

|

2 |

50 |

345 |

40 |

275 |

20 |

|

3 |

65 |

450 |

55 |

380 |

18 |

|

4 |

80 |

550 |

70 |

483 |

15 |

|

5 |

130 |

895 |

120 |

828 |

10 |

|

7 |

50 |

345 |

40 |

275 |

20 |