Factory supply High Quality NiFe alloy sputtering target

Product Description of NiFe alloy sputtering target

JINXING METAL offers a complete line of sputtering targets ranging from commercial grade to highest purity, zone refined Ultra-Pure grade. These materials can be fabricated to fit all commercially available systems or to specific dimensions required for your particular applications. A number of metallurgical techniques are employed in PVD material fabrication.

• Hot Pressing

• Hot Isostatic Pressing (HIP'ing)

• Cold Isostatic Pressing (CIP'ing)

• Vacuum Sintering

• Induction Melting

• Vacuum Melting & Casting

• Arc Melting

• Electron-Beam Melting

• Plasma Spraying

• Co-Precipitation

We are professional factory to produce all kinds of materials Disc/Planar/Rotary sputtering target. Ti sputtering target, Zr sputtering target, Cr sputtering target, Ni sputtering target, Cu sputtering target, Mo sputtering target, W sputtering target, Nb sputtering target, Ta sputtering target, V sputtering target, Al-Ti sputtering target, Ni-Cr sputtering target, Nb-Zr sputtering target, Mo-Nb sputtering target, Al alloy sputtering target, Al-Ti- Si sputtering target, Cr-al sputtering target, Si-Ai sputtering target, Ni-V sputtering target and Ti-Zr sputtering target are all mainly products.

|

ferro-nickel (NiFe) Metal |

|

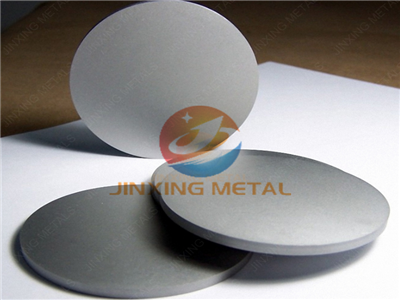

ferro-nickel (NiFe) Sputtering Targets Purity — 99.99% Shape — Discs, Plate, Step (Dia ≤300mm,, Thickness ≥1mm) Rectangle, Sheet, Step (Length ≤600mm, Width ≤300mm, Thickness ≥1mm) Tube( Diameter< 300mm, Thickness >2mm ) |

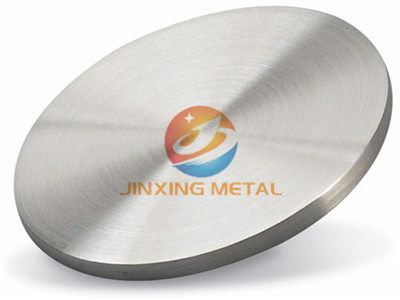

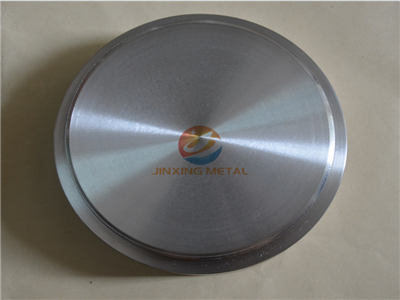

NiFe alloy sputtering target of product show

NiFe alloy sputtering target of Enhanced Design

JINXING METAL.'s unique enhanced design sputtering targets are produced for use in the sputtering of precious metals and magnetic materials, thereby increasing target utilization. Through engineering design, the enhanced profile provides utilization factors far in excess of those conventionally found in planar designed targets.

By taking the inverse of the erosion profile, thus increasing the target thickness in this area, JINXING METAL has developed long life targets with utilization approaching 100% and with longevity almost twice that of ordinary planar targets. These targets have increased volumes in the area of greatest wear and decreased volumes in areas where little or no deposition takes place. This unique capability is available for both planar and rotary designed cathode assemblies.

If you are interested in any of our products, please feel free to visit our website and contact us directly for more informations. We are looking forward to cooperate with you! https://www.matmetals.com/