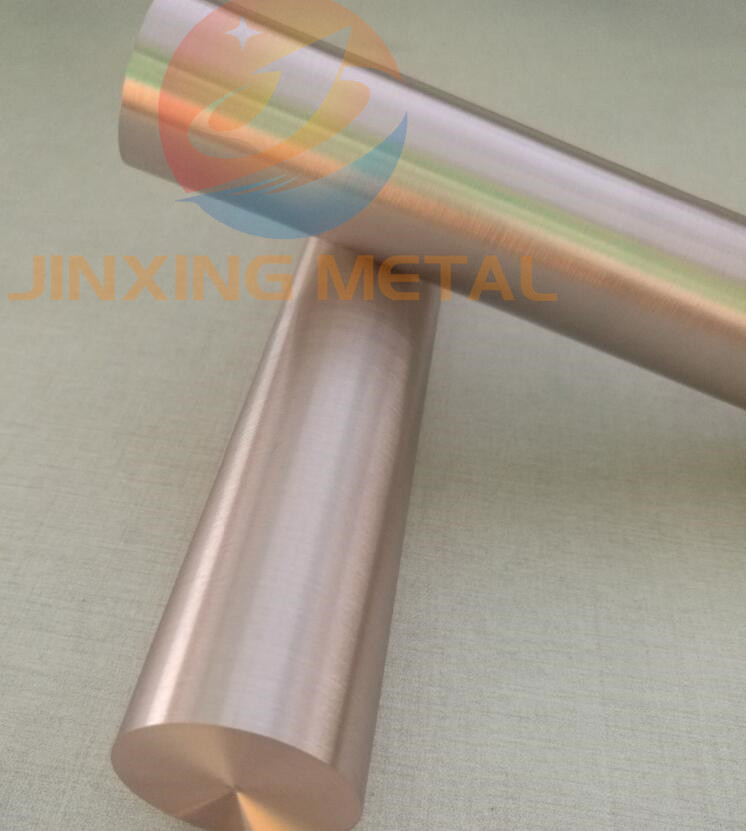

excellent quality tungsten copper alloy and copper tungsten tube made for rod/plate/sheet/block shape

excellent quality tungsten copper alloy and copper tungsten tube made for rod/plate/sheet/block shape

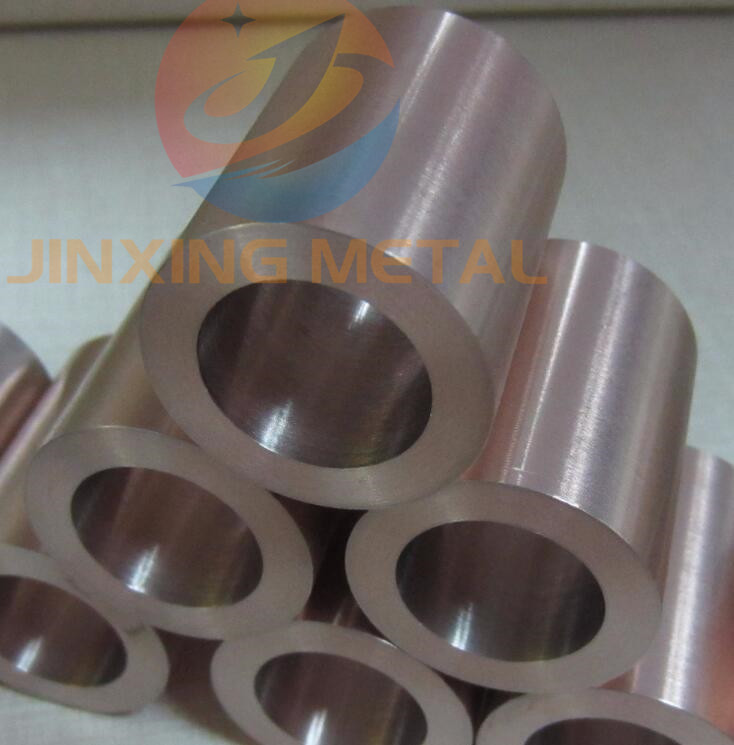

copper tungsten tube of Description

Tungsten copper alloy tube is used when a product or part needs to have a high heat resistance, low thermal expansion and high electrical or thermal conductivity. Tungsten copper alloy is used to make engines and electrical devices. It is also used in the fields of aviation and spaceflight. Electrodes, refractory parts, heat sinks, rocket parts and electrical contacts are all made out of tungsten copper alloy. The alloy is also made into sheet metal, tubing and plate metal. Tungsten copper alloy is used to make contacts for both high and low voltage electrical devices, and for high speed steel devices and switches.

Specification of copper tungsten tube:

|

Type |

Density |

Conductivity |

HB |

Size |

|

WCu50 |

11.9~12.3 |

≥55 |

1130~1180 |

Tube: ?5~290 |

|

WCu40 |

12.8~13.0 |

≥47 |

≥1375 |

|

|

WCu30 |

13.8~14.4 |

≥42 |

≥1720 |

|

|

WCu20 |

15.2~15.6 |

≥34 |

≥2160 |

|

|

WCu10 |

16.8~17.2 |

≥27 |

≥2550 |

|

|

WCu7 |

17.3~17.8 |

≥26 |

≥2900 |

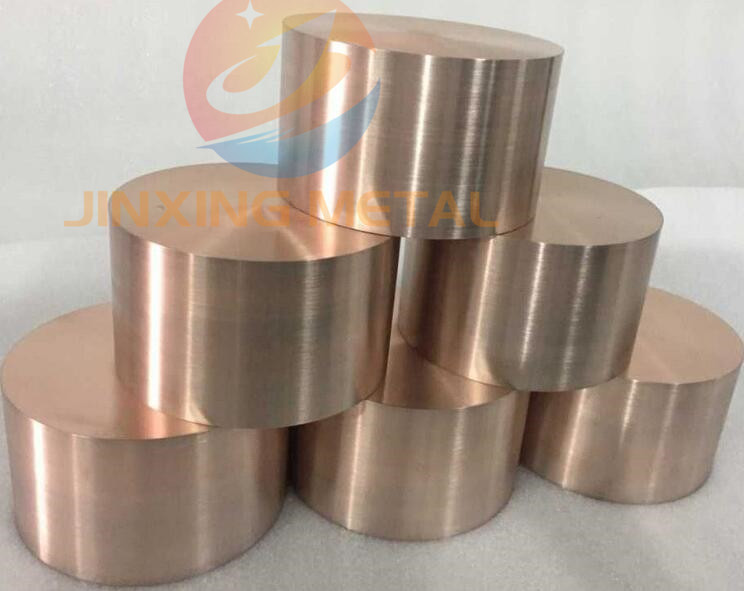

Advantages of copper tungsten tube:

Heavy Density

Free cutting processing

Excellent mechanical performance

High elastic modulus

Can effectively absorb xrays and gamma rays

(for the absorption of x rays, and gamma rays than lead high about 30% – 30%)

no harm to environment and health