Product Description

WCu Alloy Welding Electrode Wheel

Under the high requirements of the welding process on the electrode, WCu Alloy Welding Electrode Wheel has all the excellent characteristics of tungsten and copper, such as high electrical conductivity, high wear resistance, high hardness strength, strong high temperature resistance, excellent machinability, good welding seam formation, strong welding seam sealing, low thermal expansion coefficient and long service life, etc. WCu Alloy Welding Electrode Wheel is suitable for continuous welding at the junction of thin sheets and metals. It is mainly used in the sharpening process of knives (such as wire EDM and electric discharge grinding), which can ensure that the knives are not subject to thermal damage and erosion and have a long working time.WCu Alloy Welding Electrode Wheel is composed of tungsten and copper. It is mainly used for cutting stainless steel, aluminum alloy and titanium alloy materials. The tungsten content of 70%, 75% and 80% is often selected. Our company can produce different grades of tungsten-copper alloy products, if necessary, please contact us by email.

WCu Alloy Welding Electrode Wheel Specification:

|

Material |

W60Cu40,W75Cu25,W80Cu20 |

|

Technique |

Forging,Sintering,Annealing,Rolling,HIP,Machining,Injection Molding process |

|

Outer Diameter |

50-175mm |

|

Inner Diameter |

10-65mm |

|

Height |

5-40mm |

|

Conductivity (IACS) |

32-42% |

|

Density |

14.75g/cm3 |

|

Surface |

Polished,Bright,Chemical Cleaning,etc. |

|

Standard |

ASTM,GB,JIS |

|

Delivery Time |

15-20 days |

|

Certification |

ISO9001 |

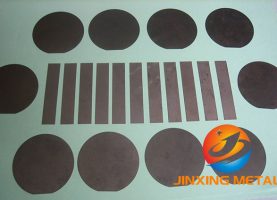

WCu Alloy Welding Electrode Wheel Picture:

Please leave your information to get the latest quotation and product catalogue!

English

English

French

French  German

German