Product Description

Overview

Tungsten Electrode Rod is a rod-shaped electrode manufactured from metallic tungsten or tungsten alloys incorporating rare earth oxides. It possesses characteristics including a high melting point, corrosion resistance, excellent electrical and thermal conductivity, and superior welding performance. Primarily employed as electrode material in processes such as TIG welding, plasma cutting, and argon arc welding, it facilitates high-quality welding of metallic materials by conducting current, initiating the arc, and maintaining arc stability. Classified by composition, they encompass various types, including pure tungsten, thorium tungsten, cerium tungsten, lanthanum tungsten, and zirconium tungsten. Analyzing the distinct properties of each electrode type is essential for selecting the appropriate material for different welding scenarios and current conditions.

Tungsten Electrode Advantages

- Its extremely high melting and boiling points ensure long-term electrode shape and dimensional stability in high-temperature applications such as arc welding and plasma cutting.

- It has excellent high-temperature thermal conductivity that quickly dissipates arc heat, preventing localized overheating and cracking in the electrode.

- Its excellent electrical conductivity and strong electron emission enable stable arc ignition without the need for additional coatings.

- The arc is concentrated and not easily dissipated, allowing precise control of the heat input area, making it suitable for precision welding and minimizing workpiece deformation.

- It balances strength and processability, allowing it to be cut, ground, and processed into specific shapes (such as pointed, domed, and flat).

- Tungsten is chemically stable and does not react with air, water, most acids, or inert gases, preventing oxidation and electrode failure.

Application

1. Welding

Tungsten Electrode Rods are core components for TIG welding and plasma arc welding, used for welding thin-walled and precision parts requiring high precision and purity, such as stainless steel, titanium alloys, aluminum alloys, and magnesium alloys (e.g., aerospace parts, medical devices, and food-grade piping).

- Plasma Processing

Using a tungsten electrode to ignite an arc, high-temperature plasma is generated for cutting, spraying, or melting. This allows for rapid, smooth, and efficient cutting of thick plates of carbon steel, stainless steel, and non-ferrous metals (e.g., copper and aluminum). Wear- and corrosion-resistant coatings can also be applied to the workpiece surface.

- Electrodischarge Machining

Utilizing tungsten's high hardness and wear resistance, the spark discharge removes workpiece material and allows for the machining of complex mold cavities.

2. Electronics

- Electron Tubes: High-power electronic devices such as radar transmitters and microwave tubes.

- In semiconductor wafer etching and thin-film deposition equipment, they serve as conductive electrodes within the vacuum chamber to prevent contamination of the wafer by volatiles.

- As heating electrodes for high-temperature growth of sapphire substrates (LED core substrates), they do not react with the substrate, ensuring substrate purity.

3. High-Temperature Industry

- In sintering furnaces and high-temperature laboratory furnaces, it can be used as a resistance heating electrode, operating directly in environments exceeding 1600°C without melting or softening.

- It can be made into a protective tube for thermocouples (temperature measuring elements), enclosing the thermocouple wire to protect the element in molten metal and high-temperature flue gases without affecting temperature measurement accuracy.

Dimension

|

Material |

Tungsten |

|

Purity |

≥99.95% |

|

Diameter |

0.5-12mm |

|

Length |

100-3000mm |

|

Density |

18.8-19.2g/cm3 |

|

Surface |

Polished |

|

Delivery Time |

7-20 days |

|

Standard |

ASTM B777,MIL-T-21014 |

|

Certification |

ISO 9001 |

Tungsten Electrode Rod Type

- Cerium-tungsten electrode (WCe): Superior electron emission capability, faster arc initiation, and more stable arc; suitable for DC TIG welding and low-current welding.

- Lanthanum-tungsten electrode (WLa): Higher high-temperature strength, lower wear rate, and excellent contamination resistance; suitable for AC/DC TIG welding and plasma welding.

- Thorium tungsten electrode (WTh): Exceptionally high electron emission efficiency and optimal arc stability; suitable for high-current precision welding (but contains radioactivity, limiting its application).

- Zirconium tungsten electrode (WZr): Excellent oxidation resistance, suitable for AC welding (e.g., aluminium alloy welding); suitable for AC TIG welding and non-corrosive environments.

Process

① Raw Material Preparation

High-purity tungsten powder (≥99.95%) is selected as the base material. Depending on the electrode type, different rare earth oxides or other additives are added. Some special electrodes also require auxiliary materials such as composite alloy steel rods.

② Mixing and Forming

Tungsten powder and additives are mixed in appropriate proportions, typically using a wet mixing method to evenly distribute the additives throughout the tungsten powder. The mixed materials are dried and pressed to form the electrode blank.

③ Sintering

The electrode blank is sintered in a high-temperature furnace to strengthen the bond between the powder particles, increasing density and mechanical strength.

④ Press Working

The sintered electrode rod undergoes plastic deformation processes such as rotary forging and drawing to further enhance density and mechanical properties, while also being machined to the desired diameter and length.

⑤ Cutting and Forming

The electrode rod is cut to custom lengths, and the ends are sharpened or spheroidized according to application requirements.

⑥ Surface Treatment

Acid pickling, polishing, or plating is used to remove surface oxides, improve surface finish, and enhance corrosion resistance. ⑦ Quality Inspection and Packaging

Finished electrodes undergo performance testing for composition, density, conductivity, thermal stability, and other properties to ensure compliance with international standards (such as AWS and ISO).

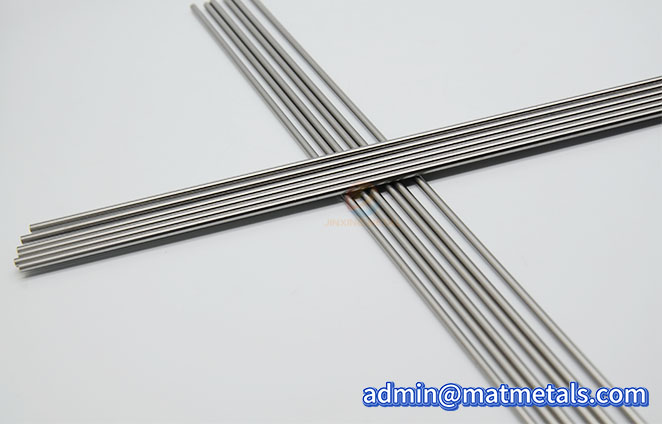

Pictures

Please leave your information to get the latest quotation and product catalogue!