Product Description

Overview

Tantalum Ta Custom Bolts are fasteners made of tantalum or tantalum alloy. They mainly connect and fix components through threaded structures. With their unique physical and chemical properties, they meet the strict requirements of material performance in aerospace, chemical, medical (such as orthopedic implants), high-temperature equipment, and other fields.

Advantages

- It has a high melting point and can maintain good strength and oxidation resistance at a high temperature of 2000℃.

- It has good chemical stability, high strength, strong corrosion resistance, and long service life.

- Tantalum is non-toxic and non-sensitizing to human tissue and has excellent blood compatibility.

- It has good processing performance and can meet the different customized requirements of customers.

Application

- In the environment of Chemical Reaction Kettle, marine engineering and lithium battery electrolyte, tantalum bolts can withstand the erosion of strong corrosive medium for a long time, and avoid the risk of fracture and leakage caused by corrosion of ordinary metal bolts.

- The capture cross section of tantalum for neutron radiation is low, and it is not easy to produce induced radioactivity in a strong radiation environment. It is suitable for fastener connections of pressure vessels and particle accelerator equipment in nuclear power plants.

- Tantalum has excellent electromagnetic shielding performance. It can be used as a low impedance grounding bolt in high frequency electronic equipment (such as radar module and 5G base station) to reduce signal interference.

- In the scenarios of aero-engine combustion chambers, nuclear reactor high-temperature parts, and electron tube filament fixation, tantalum bolts can work stably to avoid connection failure caused by high-temperature softening.

- It can be used in orthopedic implants (such as artificial joint bolts), artificial pacemaker electrode fixtures, and other medical fields, and is suitable for long-term implantation in the body, reducing the risk of rejection and infection.

Dimension

|

Grade |

R05200,R05400,R05255,R05252,R05240 |

|

Purity |

≥99.95% |

|

Size |

M2 × 0.4-M30 × 3.5 |

| Head Type | Hex、Countersunk、Socket、Pan |

|

Melting Point |

2996℃ |

|

Density |

16.65g/cm3 |

|

Surface |

Black, Alkaline cleaning, Polished |

|

Standard |

ASTM B574, GB, DIN 125/127 |

|

Certification |

ISO 9001 |

Process

①Select high-purity tantalum powder for vacuum melting.

②Forming through hot or cold processing to make round bars.

③Reduce roughness through heat treatment and surface polishing.

④Turn or mill to produce threads or grooves.

⑤Full-process testing and quality control to ensure that products meet ISO 9001 standards.

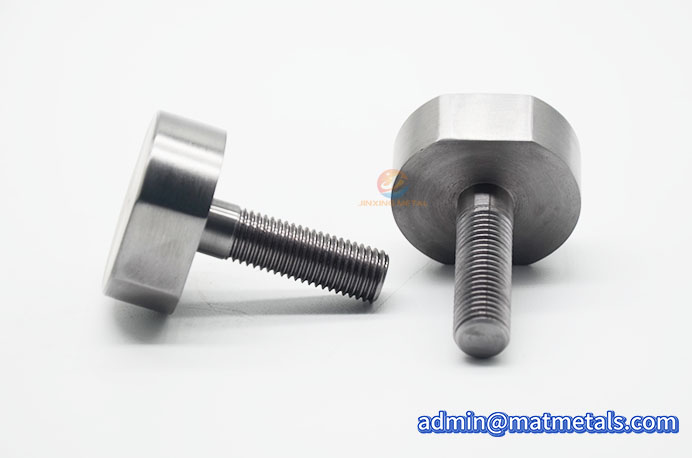

Pictures

Please leave your information to get the latest quotation and product catalogue!