Product Description

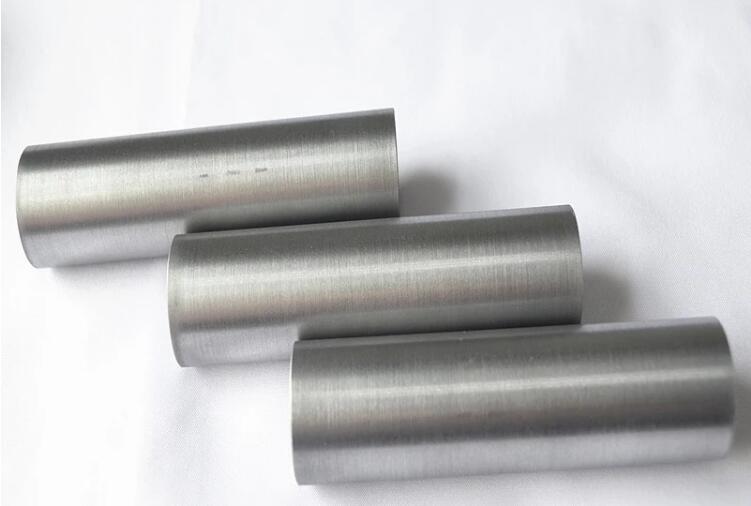

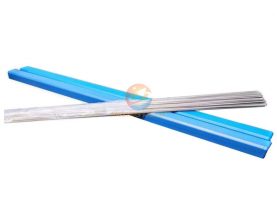

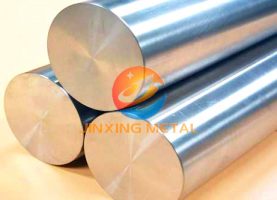

Medical Titanium Implant Rod

Titanium and titanium alloys are widely used in clinical bone repair implants because of their good biocompatibility, stable mechanical support and high bone conductivity. Medical Titanium Implant Rod is often made by powder metallurgy process, which has high affinity with human body, good environmental performance, light weight and easy installation, low elastic modulus, good ductility, good impact resistance, corrosion resistance and oxidation resistance Excellent, good wear resistance, non-magnetic and long service life and other excellent characteristics. Medical Titanium Implant Rod as an implant can not only give patients a comfortable wearing experience, but also can be stored in the human body for a long time (it will not be disturbed by external magnetic fields and affected by the corrosive environment inside the human body). Medical Titanium Implant Rod is well suited for joint replacements, dental implants, spinal screws and other support components, and is often used in implanted medical devices such as pacemakers and defibrillators. The commonly used international standards generally include ASTM F67 (pure titanium) and ASTM F136 (6AL-4V-ELI), which can be customized according to the specific implantation site. If necessary, you can email us.

|

Grade |

Ti-6AL-7Nb,Ti-6AL4VELI,Gr4 |

|

Technique |

Rolling,Bending,Welding,Cutting,Forging,Machining |

|

Purity |

≥95% |

|

Length |

50mm-3000mm |

|

Diameter |

4mm-100mm |

|

Density |

4.52g/cm3 |

|

Shape |

Round |

|

Surface |

Polishing,Grinding,Black Oxide,etc. |

|

Deliver Time |

20-30 days |

|

Standard |

ASTM F67,ASTM F136,GB |

|

Certification |

ISO9001 |

Medical Titanium Implant Rod Picture:

Please leave your information to get the latest quotation and product catalogue!

English

English

French

French  German

German