Product Description

Overview

Iridium Metal Rods are made from the rare platinum group metal iridium through a powder metallurgy process. They maintain dimensional and performance stability in extreme heat and corrosive environments, making them irreplaceable in applications such as catalyst supports, nuclear medicine equipment, high-temperature industrial components, and precision electronic components. Despite their high price, their long-term stability in extreme environments makes them the material of choice for high-end applications. We offer high-precision customization services. Please contact us by email for more product details.

Iridium Advantages

- Exceptional corrosion resistance: Iridium possesses outstanding chemical inertness, exhibiting negligible reaction with virtually all chemicals. This enables it to maintain stable performance in highly corrosive environments, making it suitable for demanding conditions in chemical processing and nuclear industries.

- High hardness and wear resistance: As a hard material, iridium offers excellent wear resistance. Its metal rods resist abrasion during prolonged use, thereby extending equipment service life.

- Superior electrical conductivity: Iridium possesses excellent electrical conductivity, making it suitable for manufacturing high-precision electrical components and sensors.

- Biocompatibility: In the medical field, iridium exhibits outstanding biocompatibility, serving as an ideal material for electrodes in implantable medical devices to ensure signal acquisition quality.

- High-temperature stability: Iridium possesses an exceptionally high melting point (2446°C), maintaining structural integrity in elevated thermal environments and rendering it suitable for high-temperature industrial applications.

- Synergistic effects with other metals: When alloyed with metals such as platinum, iridium further enhances mechanical strength, improves durability, and optimizes machinability.

Application

1. Iridium's high melting point and high-temperature stability are its core application advantages, making it particularly suitable for replacing other metals (such as platinum and nickel alloys) in ultra-high-temperature environments. Iridium metal rods are used in the nozzle throats and combustion chamber linings of liquid rocket engines (or in an Ir-Rh alloy with rhodium to further enhance high-temperature strength), where they directly contact high-temperature combustion gases and maintain structural stability.

2. Iridium rods can serve as supports in laboratory high-temperature furnaces or be processed into protective tubes to enclose thermocouples for high-precision high-temperature experiments such as metal melting and ceramic sintering.

3. Certain specialty glasses (such as optical glass and optical fiber preforms) must melt at temperatures around 2000°C. Electrodes made from iridium rods resist corrosion from the glass melt and do not introduce impurities (thus reducing the glass's light transmittance).

4. Catalysts made from iridium can stably degrade volatile organic compounds at temperatures between 300°C and 500°C without generating secondary pollution.

5. Iridium's stable conductivity and good compatibility with semiconductor materials (such as silicon and sapphire) make it suitable for high-end electronic devices. Iridium thin-film electrodes (deposited from rods via a sputtering process) can be combined with high-dielectric-constant materials to significantly improve the storage density and leakage stability of capacitors.

5. Iridium has excellent biocompatibility (non-toxic and non-reactive with human fluids), and its radioactive isotopes can be used in surface coatings for dental implants, implantable medical devices, and radiotherapy.

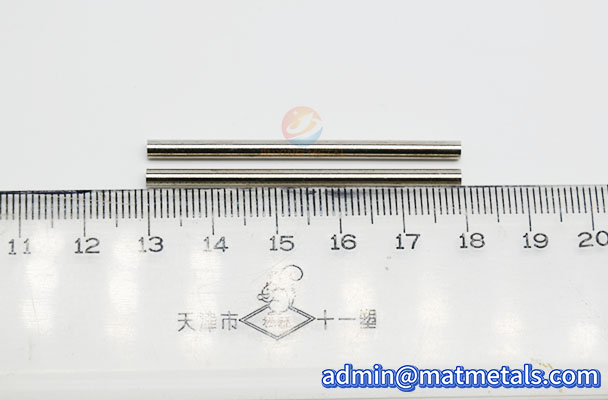

Iridium Rods Dimension

|

Material |

Ir |

| Purity | ≥ 99.0%-99.99% |

|

Diameter |

5m-300mm |

|

Length |

100-2000mm |

| Tolerance |

±0.01 mm-±0.5 mm |

|

Density |

22.56g/cm3 |

| Melting Point |

2454℃ |

|

Shape |

Round |

|

Delivery Time |

15-20 days |

|

Surface |

Alkaline Cleaning, Polishing |

|

Standard |

ASTM, GB |

|

Certification |

ISO 9001 |

Process

Refining high-purity iridium powder → Using mold powder metallurgy to make billets (cold isostatic pressing or hot pressing and sintering) → Thermal processing (free forging and hot rolling) → Cold processing to improve precision (continuous drawing and intermediate annealing) → Straightening and cutting → Surface grinding and polishing → Quality inspection → Vacuum packaging and delivery.

Pictures

Please leave your information to get the latest quotation and product catalogue!