Product Description

ASTM B702 RWMA Class 11 Copper Tungsten Bar

Copper Tungsten Bar produces a dense, hard metal of superior wear resistance and strength at elevated temperatures. In addition, it possesses good thermal and electrical conductivity. Suited for projection welding electrodes, electro-forming and electro-forging electrodes facings for upsetting of studs and rivets, cross-wire welding of large diameter wire and rod, flash and butt welding electrodes, spot welding electrodes, light upsetting and seam welding bushings. Harder than Class 10 and used where moderate pressure is required.

Typical properties and composition of copper tungsten bar

|

Composition |

Density |

Hardness |

Resistivity |

IACS |

Bending strength |

|

wt. % |

g/cm3≥ |

HB Kgf/mm2≥ |

μΩ.cm≤ |

%≥ |

Mpa≥ |

|

W50/Cu50 |

11.85 |

115 |

3.2 |

54 |

– |

|

W55/Cu45 |

12.30 |

125 |

3.5 |

49 |

– |

|

W60/Cu40 |

12.75 |

140 |

3.7 |

47 |

– |

|

W65/Cu35 |

13.30 |

155 |

3.9 |

44 |

– |

|

W70/Cu30 |

13.80 |

175 |

4.1 |

42 |

790 |

|

W75/Cu25 |

14.50 |

195 |

4.5 |

38 |

885 |

|

W80/Cu20 |

15.15 |

220 |

5.0 |

34 |

980 |

|

W85/Cu15 |

15.90 |

240 |

5.7 |

30 |

1080 |

|

W90/Cu10 |

16.75 |

260 |

6.5 |

27 |

1160 |

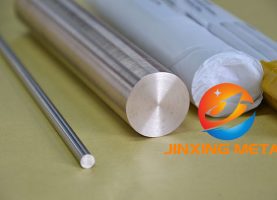

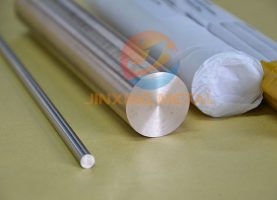

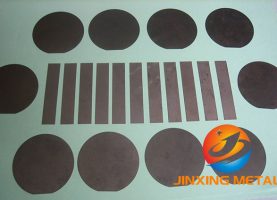

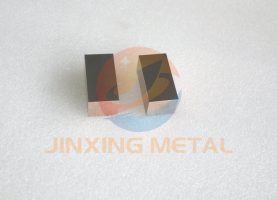

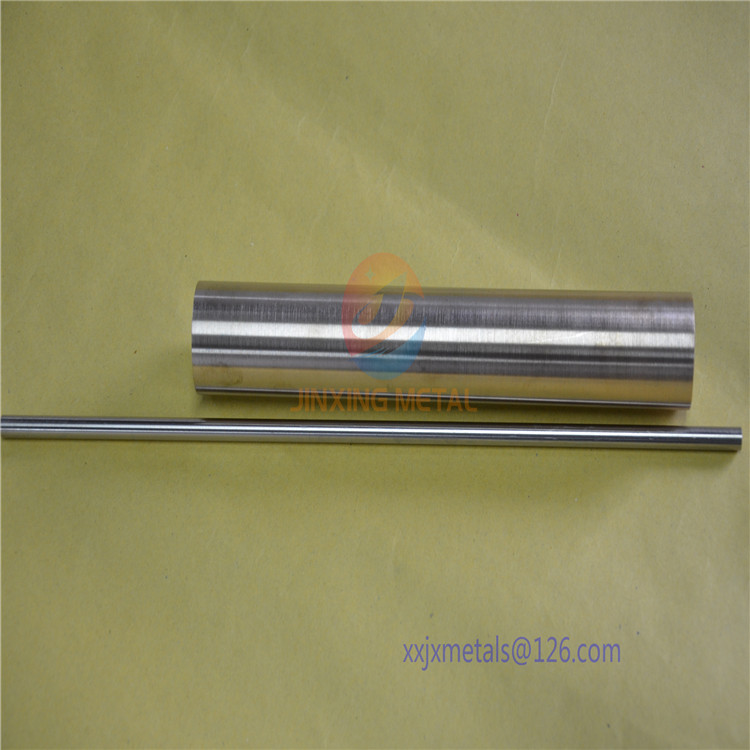

Copper Tungsten Bar Picture:

Application of copper tungsten bar

Copper tungsten bar is used where the combination of high heat resistance, high electrical and thermal conductivity, and low thermal expansion are needed. Some of the applications are in electric resistance welding, as electrical contacts, and as heat sinks. As contact material, the composite is resistant to erosion by electric arc. WCu alloys are also used in electrodes for electrical discharge machining and electrochemical machining.

Please leave your information to get the latest quotation and product catalogue!

English

English

French

French  German

German