Product Description

YG8 Carbide Rivets Description

We can use powder metallurgy and EDM for production, and strict quality control is carried out in each process.

Powder metallurgy: accurately weigh and mix tungsten carbide powder and cobalt binder – mold pressing – high temperature sintering – grinding – polishing.

EDM: make corresponding electrodes according to the shape and size of rivets – clamp carbide blanks and electrodes on the machine separately – start EDM machine to melt and weld materials – cleaning.

Features

- Extremely high hardness, outstanding wear resistance, long service life, and high cost performance.

- High strength, good compressive resistance, fatigue resistance, and not easy to break and deform.

- Good high temperature resistance, low thermal expansion coefficient, and strong dimensional stability.

- Excellent corrosion resistance and oxidation resistance.

Application

YG8 Carbide Rivets can be widely used in various heavy industrial fields such as aerospace, mining, engineering machinery, precision instruments, automobile manufacturing, petrochemicals, marine engineering and mold manufacturing.

- Used for fastening connections in high-temperature areas such as aircraft engine turbine blades and combustion chamber components, as well as riveting of fuselage frames and landing gear load-bearing structures.

- Used for fixing the lining of chemical reactors and riveting pipelines of seawater desalination equipment.

- Used for connecting automobile suspension brackets, chassis and body to ensure stability and safety of operation.

- Used for fixing optical lens brackets and connecting semiconductor packaging equipment components.

It can fully exert its excellent performance in three application environments:

Extreme environment: high temperature, high corrosion, high dust, and wear scenarios.

High load conditions: withstand high pressure, alternating stress or impact load.

Precision and long life requirements: scenarios requiringa long-term stable connection in precision instruments or molds.

YG8 Carbide Rivets Parameters

|

Grade |

YG8 |

|

Purity |

WC:≥88-95%,Co:5-12% |

|

Size |

M12-35 |

|

Density |

14.0g/cm3-15.1g/cm3 |

|

Hardness |

≥87-90.5 HRA |

|

TRS |

≥1600-3100 N/mm2 |

|

Surface |

Alkaline cleaning, High Polished, Blank |

|

Standard |

GB, ASTM |

|

Delivery Time |

20 days |

|

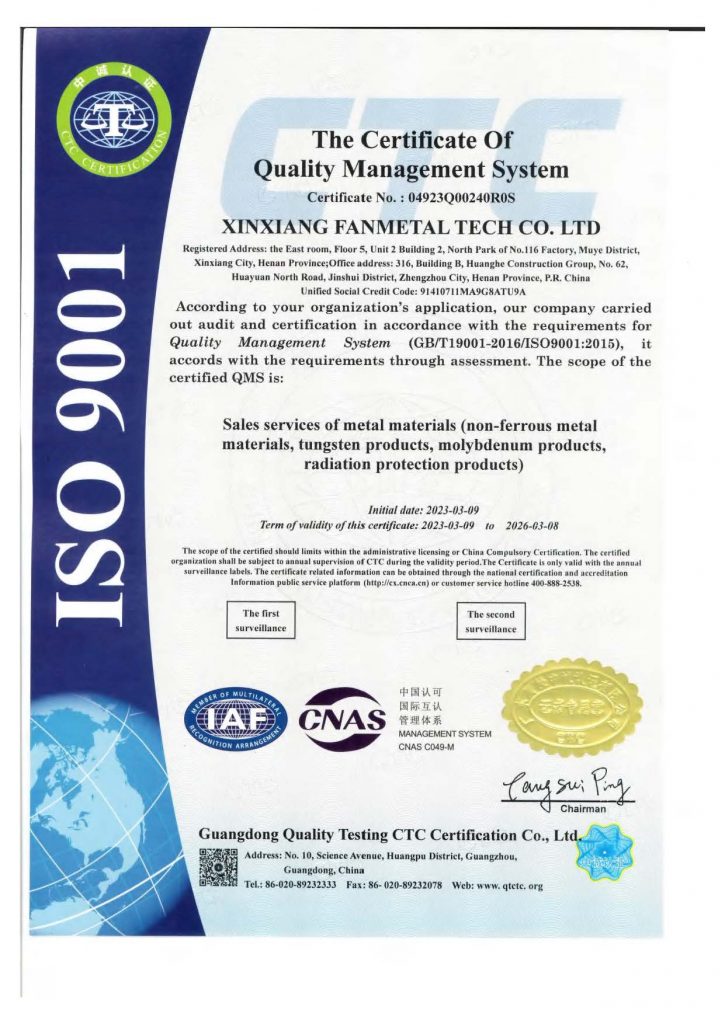

Certification |

ISO 9001 |

YG8 Carbide Rivets Pictures

Product Qualification

Please leave your information to get the latest quotation and product catalogue!