Product Description

Overview

Molybdenum is a refractory rare metal like tungsten. WMo Alloy Wire is an alloy wire composed of these two elements. The tungsten content in the commonly used alloy is 30% to 50%. Due to its good high-temperature strength, similar performance to tungsten but smaller specific gravity than tungsten, it can be used as filaments, parts and other high-temperature materials of electron tubes under corresponding high-temperature conditions.

Advantages

- Physics: high melting point, low evaporation loss at high temperature, good conductivity.

- Chemical: at room temperature, for most of the acid-base medium, corrosion resistance, as well as good high-temperature oxidation resistance.

- Mechanics: high tensile strength, high hardness, good ductility, can be customized for processing.

- Thermal: Coefficient of thermal expansion of molybdenum, suitable for use in environments of drastic changes in temperature, and heat dissipation capacity.

Application

- Electronic and electronic vacuum devices: such as vacuum tube filament, cathode support structure, high temperature wire, etc. .

- High temperature furnace components: used as heating wire, temperature measuring elements, high temperature wire drawing furnace electrode and support structure.

- Non-ferrous metal melting: can be made into a stir bar or guide tube, resistant to molten metal erosion and high temperature oxidation.

- Aerospace: manufactures high temperature components (e., rocket nozzle attachments, combustion chamber support structures) , high temperature sensors, etc..

- Semiconductors and integrated circuits: supporting structures used as sputtering targets, electrode materials, or in high-temperature processes.

WMo Alloy Wire Specifications

|

Grade |

Mo50W50/Mo70W30 |

|

Diameter |

0.05–2mm |

|

Length |

20-2500mm |

|

Density |

10.2g/cm3 -19.2g/cm3 |

|

Surface |

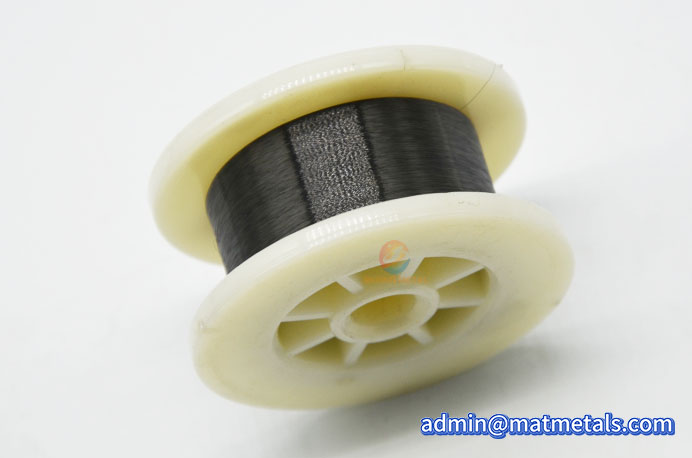

Polished, Chemical Cleaning, Black Oxide |

|

Shape |

Coil |

|

Delivery time |

7-20 days |

|

Standard |

ASTM B777,GB |

|

Certification |

ISO 9001 |

Process

WMo Alloy Wire adopts the method of combining powder metallurgy with plastic processing. Its core process can be divided into six stages: raw material preparation, alloying, forming, densification, wire drawing and post-processing.

① Select high-purity tungsten powder and molybdenum powder for reasonable composition mixing,

② Cold pressing or isostatic pressing to make a billet.

③ Densification treatment after high-temperature vacuum sintering.

④ Forging, rolling, multiple wire drawing, and annealing treatment to ensure dimensional accuracy and toughness.

⑤ Surface cleaning and precision cutting, as well as comprehensive quality inspection.

Pictures

Please leave your information to get the latest quotation and product catalogue!