Product Description

Overview

Titanium MIG Wire is a specialized titanium-based welding material adapted for MIG welding processes. Available in two main series: pure titanium and titanium alloys, it combines the core advantages of titanium—lightweight yet high-strength, highly corrosion-resistant, and biocompatible—making it a key consumable for welding titanium components in high-end fields such as aerospace, medical, and chemical industries. We offer grades including ERTi-5 (Ti-6Al-4V) and ERTi-23 (medical ultra-low gap), and also accept custom production based on provided drawings. For more product details and pricing, please feel free to contact us via email or WhatsApp.

Titanium Wire Features

- Lightweight and high-strength, with a density of only 4.51 g/cm³, approximately 60% that of steel, yet its tensile strength reaches or even exceeds that of some high-strength steels.

- A dense, stable, and strongly adherent titanium oxide passivation film spontaneously forms on the surface of titanium materials. This film remains stable in most acidic and alkaline media and highly corrosive environments, exhibiting corrosion resistance far exceeding that of traditional metal wires such as stainless steel and copper.

- It possesses stable mechanical properties, exhibiting no brittle fracture at low temperatures and maintaining high strength and oxidation resistance at high temperatures, making it suitable for extreme temperature variations.

- It is non-magnetic, possessing a certain degree of elasticity and plasticity, allowing for various processing methods such as cold bending, weaving, and welding, making it suitable for applications requiring thermal insulation and electrical insulation.

- It is non-toxic, non-allergenic, and has an extremely high affinity for human tissue and blood, preventing rejection reactions. Furthermore, its elastic modulus is close to that of human bone, enabling bone repair.

Titanium MIG Wire Dimension

| Grade | ERTi-1/ERTi-2/ERTi-4/ERTi-5/ERTi-7/ERTi-23 |

| Diameter | 0.8mm-5mm |

| Length | 250mm-3000mm |

| Density | 4.5g/cm³ |

| Tensile Strength | ≥345-900MPa |

| Shape | Straight |

| MOQ | 5KG |

| Standard | AWS A5.16 |

| Certification | ISO 9001 |

Titanium Welding Wire Application

1. Aerospace Industry

This is one of the core application areas for titanium MIG welding wire, primarily using grades such as ERTi-5 (Ti-6Al-4V) and ERTi-3.

It is used for welding aircraft fuselage frames, wing structures, engine nacelle components, spacecraft supports, and rocket propulsion system piping. The lightweight and high-strength of titanium alloys significantly reduces aircraft weight, improving range and payload capacity, while the high efficiency of MIG welding meets the precision and schedule requirements of mass production of aerospace components.

2. Marine Engineering and Shipbuilding

Grades such as ERTi-7 (Ti-6Al-4V+Pd) and ERTA9 (Ti-Pd alloy), which are resistant to seawater corrosion, are preferred. They are used in heat exchange tubes and shells of seawater desalination equipment, corrosion-resistant support structures for offshore platforms, and titanium alloy components for ship propulsion systems, resisting long-term corrosion in high-salinity, high-humidity marine environments and extending equipment lifespan.

3. Chemical and Petrochemical Industries

Commonly used grades include ERTi-9 (Ti-3Al-2.5V) and ERTi-12, which are resistant to strong corrosion. They are used for welding chemical reactors, corrosion-resistant pipelines, electrolytic cells in the chlor-alkali industry, and heat exchangers in petroleum refining. Joints welded with MIG welding wire can withstand harsh media such as strong acids, strong alkalis, and strong oxidants, preventing safety accidents caused by corrosion leaks.

4. Medical and Healthcare Industries

Primarily using medical-grade ERTi-23 welding wire (Ti-6Al-4V ELI, ultra-low gap element). Used for welding precision medical devices such as artificial joints (hip and knee joints), orthopedic implant plates, dental implant abutments, pacemaker housings, and medical catheters, meeting sterile, non-rejection, and long-term stable medical standards.

5. Automotive and High-End Manufacturing

ERTi-5 welding wire is used for welding lightweight chassis and motor housings in high-end racing cars and new energy vehicles to achieve weight reduction and increased strength. It is also used for welding precision instruments and military equipment.

Straight Titanium Wire Process

①The smelted titanium ingots are free-forged or die-forged under vacuum at 800℃~1050℃ to refine the grain size, forging the ingots into titanium billets in preparation for subsequent rolling.

②Multi-pass hot rolling is then performed to gradually reduce the diameter, rolling the billets into titanium wire rods. This significantly improves the plasticity and density of the billet while controlling its dimensional accuracy.

③At room temperature, the titanium wire rods are stretched multiple times using a drawing die to gradually reduce the diameter to the target specification; alternatively, the billet can be heated to 200℃~400℃ before drawing, suitable for forming large-diameter or high-strength titanium alloy straight wires (such as Ti-6Al-4V).

④Intermediate annealing is performed in a vacuum environment to eliminate work hardening generated during drawing, restore the plasticity of the titanium wire, and ensure smooth operation of subsequent processes.

⑤A straightening process is used to gradually correct the curvature of the wire and eliminate residual stress within the wire.

⑥After cutting to length, pickling and polishing are performed to remove the oxide layer and machining burrs, improving surface finish.

⑦Conduct comprehensive quality inspections (dimensional accuracy, mechanical properties, surface finish, chemical composition) to ensure products meet quality standards before shipment.

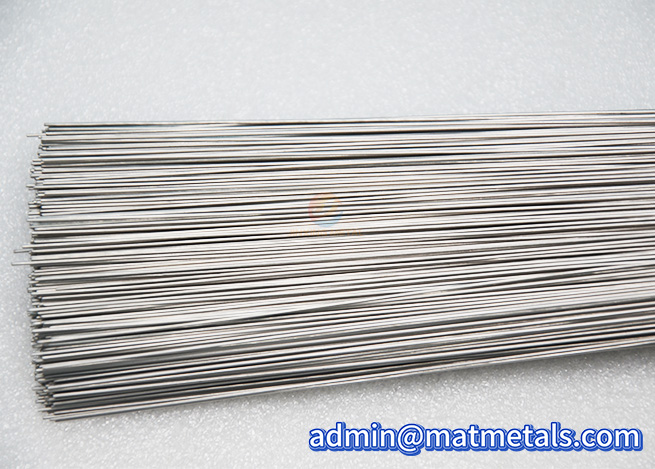

Titanium MIG Wire Pictures

Packing

Please leave your information to get the latest quotation and product catalogue!