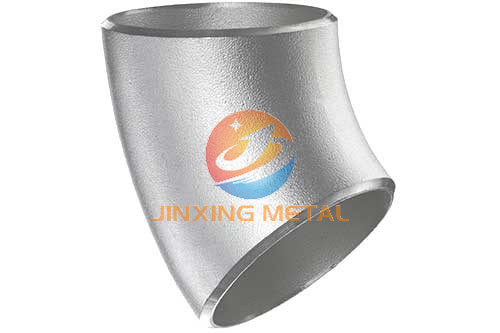

Product Description

Titanium elbow specifications:

|

TITANIUM PIPE FITTINGS DETAILS |

||

|

Name |

Elbow |

|

|

Material |

Titanium |

Gr1 Gr2 Gr3 Gr5 Gr7 Gr9 Gr12 |

|

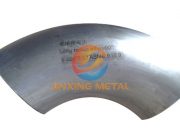

Standard |

ASME B16.9, ANSI B16.9, ASTM , JISB2312,DIN,BS, GBT12459-05, GB13401-05,GOST |

|

|

ASME B16.9-2007,MSS SP 43-1991,MSS SP-75,ASTM B363 |

||

|

Size |

1/2"-96" DN15-DN2400 |

|

|

Wall thickness |

Sch5S, Sch10S, Sch40S, Sch80S Sch10,Sch20,Sch30,STD,Sch40,Sch60,XS,Sch80,Sch100,Sch120,Sch140,Sch160,XXS |

|

|

Type |

Butt welded or Seamless |

|

|

Shape |

Equal or Reducing |

|

|

Product |

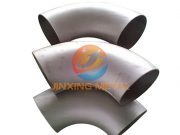

1. Elbow L/R & S/R (45/90/180 DEG) according to customer’s requirement can produce the other's degree, such as 22.5 degree 30 degree 60 degree etc. |

|

|

2. Tee(Straight and Reducing) |

||

|

3. Reducer(Concentric and Eccentric) |

||

|

4. Cross |

||

|

5. Cap(Round and Elliptical) |

||

|

6. Stub End |

||

|

Surface |

Black painting ; Pickling ; Sand blasting |

|

|

Certificate |

ISO9001 ; ISO9001:2008 |

|

|

Package |

Wood case or Wooden pallets or according to the customer's requirements. |

|

|

Lead Time |

Within 30 days or according to the customer's requirements. |

|

|

MOQ |

10 Piece |

|

|

OEM |

YES |

|

Detailed Description£º

ASME B16.9 Factory –Made Wrought Buttwelding FittingsASME B16.25 Buttwelding EndsASME B36.10 Welded and Seamless Wrought Steet PipeASME B36.19 Stainless Steel Pipe

ASME B31.3 Process Piping

ASME B16.5 Pipe Flanges and Flanges [NPS1/2 Through NPS24] Metric/Inch Standard £¨NPS1/2~NPS24

ASME B16 .47 Large Diameter Steel Flanges NPS 26 Through NPS 60 Metric/Inch Standard

ASTM B861 Standard Specification for Titanium and Titanium Alloy Seamless Pipe

ASTM B862 Specification for titanium and Titanium and Alloy Welding Pipe

ASTM B381 Standard Specification for Titanium and Titanium Alloy Seamless Forgings

MSS SP-97 Integrally Reinforced Forged Branch Outlet Fittings-Socket Welding£¬Threaded and Buttwelding Ends

MSS SP-43 Wrought Stainless Steel Butt¬—Welding Fittings

AWS A5.16/A5.16M-2007 Specification for titanium and Titanium and Alloy Welding Electrodes and Rods

GB/T27684-2011

GB/T20623-2009

HG/T3651-1999

HG/T20592-2009

GB/T12459-2005

GB/T13401-2005

GB/T19326-2003

Our Services

Quality is the soul of our company!

We track every production process, inspect every single part, and record every step, for we know that "Quality first" is always our principle.

1.Provide third-part inspection reports.

2.Visual inspection to check surface quality, ensuring without flaw, black dot and any other defects.

3.Ultrasonic Flaw Detection making sure there are no defects inside.

4.Chemical Compositionmaking sure all chemical components can satisfy customer's demands

5.Mechanical Property testingmaking sure all titanium bars have satisfying mechanical features before delivery.

6.ISO Quality Management System-SGS test

Please leave your information to get the latest quotation and product catalogue!