Product Description

Overview

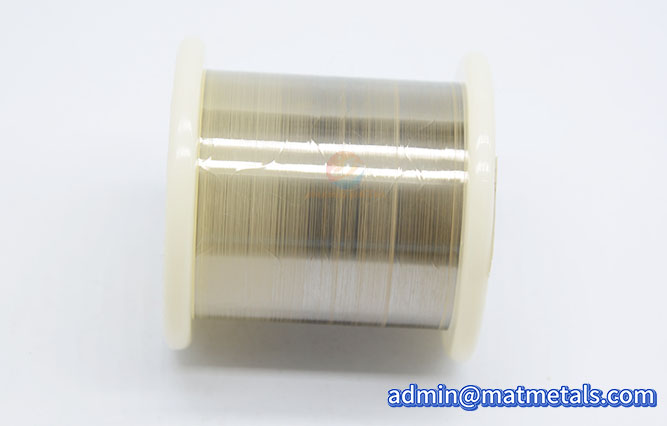

Nickel Chromium Wires are electric heating elements with high resistivity and heat resistance. They are widely used as heating elements in devices such as electric furnaces, soldering irons, and electric irons. Despite their high price, they are an indispensable component in many industrial and household devices due to their excellent oxidation resistance, high-temperature strength, and good processing properties.

Advantages

- Excellent high-temperature resistance, maintaining stable physical and chemical properties in high-temperature environments, with a maximum operating temperature of 1200°C or higher.

- Excellent oxidation resistance: a dense chromium oxide film forms on the surface, preventing further oxidation of the metal inside, thereby extending service life.

- High ductility and plasticity allow it to be drawn into extremely fine wire, making it easy to weld and bend, facilitating installation and maintenance.

- High resistivity allows the required heating power to be achieved without requiring very long wire lengths, saving space and materials.

Application

- Precision Instruments: Used in resistors and potentiometers to create resistance coils, ensuring accurate current and voltage control in electronic circuits.

- Sensors: Used in components such as humidity sensors and gas sensors that require operation at specific temperatures, they maintain a constant operating environment and improve sensor detection accuracy.

- Aerospace: Nickel Chromium Wires operate stably in harsh conditions such as high altitude, low temperature, and vacuum. They are used as de-icing heating wires in aircraft cabins and as insulation heating components in spacecraft (maintaining the operating temperature of instruments in extremely low-temperature environments).

- High-Temperature Furnace Industry: Frequently used as core heating components in metal heat treatment furnaces and melting furnaces, they operate stably and long-term at high temperatures (typically 500°C to 1200°C), ensuring temperature accuracy in industrial production.

- Mold Manufacturing: Inserting heating rods or heating plates made of Nickel Chromium Wires into equipment that requires preheating or constant temperature, such as plastic molding molds and rubber vulcanization molds, ensures uniform heating of the mold and improves product quality.

Dimension

|

Grade |

Cr20Ni80/Cr15Ni60 |

|

Diameter |

Φ0.09-10mm |

|

Length |

≤3000 mm |

|

Density |

8.4g/cm3 |

|

Surface |

Polishing, Bright |

|

Standard |

ASTM B161, ASTM B622 |

|

Certification |

ISO 9001 |

Process

① Accurately weigh nickel, chromium, and other trace elements according to the target alloy composition to ensure uniform composition.

② The raw materials are placed in an electric arc furnace, vacuum induction furnace, or other equipment, where they are melted at high temperatures to remove impurities and form a uniform alloy melt.

③ The molten alloy is poured into a mold and cooled to form an ingot, which serves as the billet for subsequent processing.

④ Hot rolling and cold drawing are performed, gradually reducing the diameter through a mold (such as a wire drawing die) to obtain the desired fine wire.

⑤ Annealing is performed intermediately to eliminate internal stress, soften the material, and stabilize its dimensions and properties.

⑥ Surface pickling or polishing improves surface finish and reduces heat loss during use.

Pictures

Please leave your information to get the latest quotation and product catalogue!