Product Description

Overview

Iridium spooled iridium wire is an ultrafine functional wire made from platinum group metal iridium through powder metallurgy and multi-pass cold drawing. With its high melting point, extremely strong resistance to oxidation and corrosion, high tensile strength, and excellent biocompatibility, it has become an irreplaceable microstructural material for extreme environments such as aero-engine ignition electrodes, thermocouple materials, precision electronic components, and deep brain stimulation medical electrodes. We can offer our customers the most satisfactory price; please feel free to contact us if needed.

Iridium Advantages

- High melting point with excellent high-temperature stability, capable of sustained operation above 2000°C without melting or softening.

- Good electrical conductivity with stable resistance at elevated temperatures, suitable for use as thermocouple positive electrode material (paired with rhodium, enabling measurement up to 2100°C).

- Exceptional oxidation resistance and corrosion resistance, withstanding attack from virtually all acids (including aqua regia), alkalis, and molten salts.

- Extremely high strength and hardness, coupled with favorable cold workability, permit drawing into ultra-fine wires below Φ0.01 mm.

- Non-toxic, non-allergenic, and exhibiting excellent biocompatibility.

Iridium Spooled Ir Wire Dimension

|

Material |

Ir/PtIr |

|

Purity |

≥99.9% |

|

Diameter |

0.151mm |

|

Density |

22.56 g/cm³ |

|

Melting Point |

2446°C |

|

Tensile Strength |

2000–3000 MPa |

|

Standard |

ASTM B684 |

|

Certification |

ISO 9001 |

Iridium Wire Application

1. Aerospace

Used in the manufacture of spark plug center electrodes for aircraft engine igniters, satellite thruster nozzles (iridium coating + iridium wire reinforcement), and arc-resistant ablation electrode wires.

2. High-Temperature Industrial Applications

Combined with metals such as rhodium to form thermocouples capable of measuring temperatures exceeding 1800°C, employed for temperature monitoring in metallurgical furnaces, glass melting furnaces, and similar equipment.

Under inert gas protection, they serve as heating elements in ultra-high-temperature furnaces for sintering special materials or experimental purposes.

3. Electronics and Precision Manufacturing

Employed in high-specification relays, switches, or instrumentation to ensure contact points remain wear-resistant and oxidation-free during prolonged operation.

Replaces tungsten filaments in specialized light sources (e.g., high-end projection lamps, ultraviolet lamps) to enhance longevity and stability.

4. Medical and Scientific Research

Manufactures components for medical implants, such as conductive wires in pacemakers and precision connectors for orthopaedic surgery.

Serves as consumable components in mass spectrometers and vacuum equipment, including ion source filaments and vacuum seals, exhibiting resistance to high vacuum conditions and chemical corrosion.

Ir Wire Process

① Obtain high-purity iridium powder through chemical purification (e.g., carbonylation process), typically requiring a purity of 99.95% or higher to ensure stable performance of subsequent products.

② Press the powder into cylindrical or rod-shaped billets under high pressure, then sinter the billets in a high-temperature furnace to densify them, forming initial billets with a certain strength.

③ The sintered billet is heated to 1200-1500°C for hot forging or hot rolling to preliminarily reduce its cross-sectional area.

④ The hot-worked rod undergoes multiple passes of cold drawing through wire drawing dies at room temperature. Intermediate annealing is required to relieve work hardening and restore plasticity.

⑤ Using higher-precision dies, continue multi-pass cold drawing to refine the diameter to the target specification.

⑥ Remove surface oxide layers and scratches through chemical or mechanical polishing to reduce surface roughness, meeting the high cleanliness requirements of electronic or medical applications.

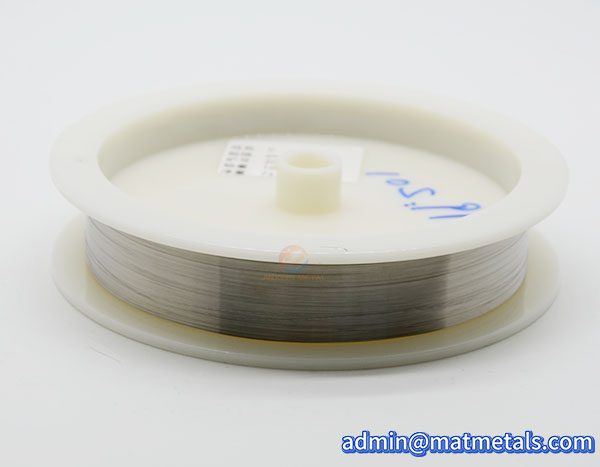

Iridium Spooled Ir Wire Pictures

Packing

Please leave your information to get the latest quotation and product catalogue!