Product Description

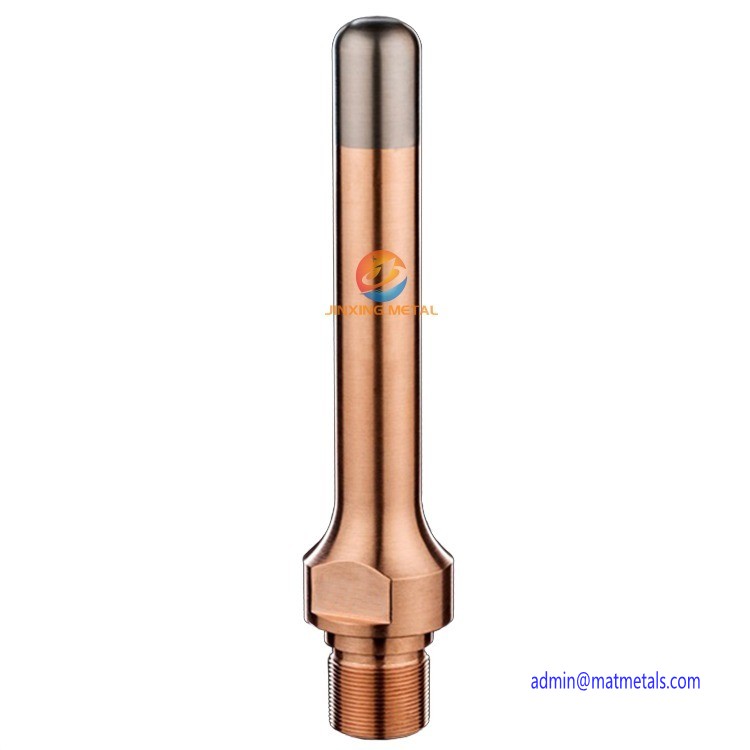

Tungsten Copper Nut Electrode Introduction

ELKONITE Welding Electrode, RWMA Class 10, RWMA Class 11, RWMA Class 12 welding electrode

The trajectory of tungsten copper sealing weld electrode is seam-like, so it also known as seam welding electrode or parallel sealing weld electrode, which is one kind of resistance welding electrode.

Advantages

1. High machining accuracy, the small area of the welding sharp;

2. Low voltage required, high-performance welding and good welding stability;

3. High torsional strength can effectively ensure the quality and precision of processing;

4. Small welding seam, good consistency and not easily to be pseudo soldered.

|

RWMA Class/(Temper) |

Alloy Number |

Hardness |

Conductivity(%) |

Tensile Strength |

|

Class 10 |

55W; 45CU |

B77 |

53 |

110 ksi |

|

Class 10 |

70W; 30CU |

B95 |

48 |

140 ksi |

|

Class 11 |

75W; 25CU |

B98 |

45 |

150 ksi |

|

Class 12 |

80W; 20CU |

B103 |

41 |

170 ksi |

Tungsten Copper Nut Electrode picture

Principle

In the process of sealing welding process, electrode are moving and rotating at same time (through electrode wheels), under constant pressure chopping energization between the electrodes, due to the contact resistance between the electrode plate and the cover plate and the frame and welding, the welding current in the contact resistance at the two Joule heat is generated, so that it is locally formed between the cover plate and frame molten solder to form solder after solidification. Therefore, except the materials of contact tips, there are many factors affecting the quality of sealing weld, such as welding current (voltage, power), welding pressure and welding speed.

Application

It is generally in vacuum or nitrogen atmosphere, tungsten copper sealing weld electrode can better ensure the hermeticity. Currently, tungsten copper sealing weld electrode mainly used for:

1. Crystal resonator industry: processed into packer module, semi-oscillations and the like;

2. Transistor packaging industry: processed into sealing mold electrode;

3. Suitable for Kovar, welding nickel-plated, gold-plated surface of the workpiece material.

Tungsten Copper Nut Electrode plays an important role in ensuring the quality of spot welding, which includes conductivity, transfer the pressure and rapidly scatter the heat in the welding area.

Tungsten Copper Nut Electrode Process

1. Special conditions for improving the contacted resistance and heat dissipation, capacitor discharge welder using large current and short energizing time can be relatively large weld the workpiece large in thickness;

2. Use electrode with different diameter and the small one used in the thin plate or the one with good performance in electrical and thermal conductivity in order to increase the current density and reduce the effect of electrode heat dissipation this side;

3. Use different electrode materials or conductive sheets, one side of the workpiece with good thermal conductivity is poor heat conductivity of copper alloy, to reduce heat loss that side;

4. Use gasket (poor performance in thermal conductivity, thickness is between 0.2-0.3mm) to reduce the heat on this side.

Please leave your information to get the latest quotation and product catalogue!

English

English

French

French  German

German