Product Description

One of the most important applications of tungsten-copper alloys is welding, which is used to conduct electricity and generate the high temperatures needed to melt metal parts and form a strong bond. Copper Tungsten Erosion Welding Electrode Wheel is an important part of the welding process. They hold the electrode in place and rotate it at a constant speed to ensure uniform wear and a smooth surface. Suppose the electrode wheel is not properly maintained or the electrodes are not properly positioned. In that case, it can lead to a phenomenon called seam corrosion, which can weaken the weld and cause leakage or failure. Copper Tungsten Erosion Welding Electrode Wheel is often used in resistance welding, electrical contact, and radiator, and it is most suitable for EDM, especially in the surface repair of PCD tools and the thin plate welding of engines, rockets, and sealed containers.

Copper Tungsten Erosion Welding Electrode Wheel Features

1. It not only has the high melting point and long service life of tungsten but also has the high conductivity of copper

2. Small electrode loss, high processing efficiency, high welding quality

3. Can withstand high-intensity continuous discharge impact, strong resistance to arc corrosion, less spark splash

4. High-temperature resistance, high thermal conductivity, high heat dissipation performance

5. The risk of joint corrosion is greatly reduced, and a strong, long-lasting weld can be achieved

Copper Tungsten Erosion Welding Electrode Wheel Specifications:

|

Grade |

70/30,75/25 |

|

Technique |

Rolling, HIP, Machining, Injection Molding process |

|

Outer Diameter |

125-175mm |

|

Thickness |

5-10mm |

|

Height |

20-60mm |

|

Hardness |

85-100HRB |

|

Density |

14.1-15.3g/cm3 |

|

Surface |

Polished, Bright, Chemical Cleaning |

|

Standard |

ASTM B702, GB,JIS |

|

Certification |

ISO9001 |

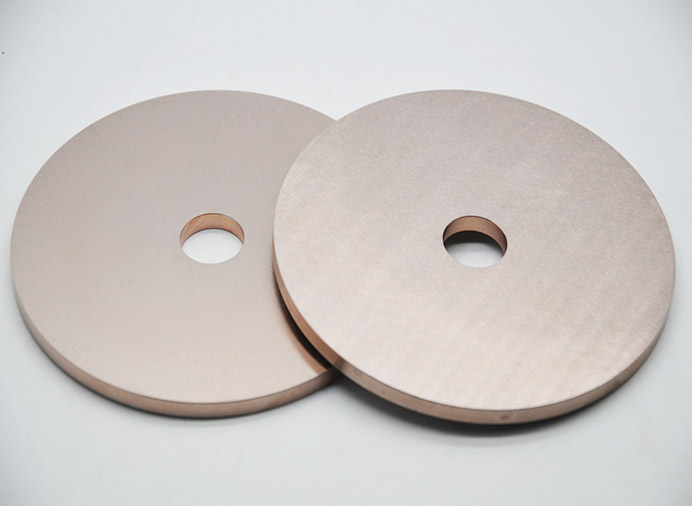

Copper Tungsten Erosion Welding Electrode Wheel Picture

Please leave your information to get the latest quotation and product catalogue!