Product Description

Overview

Zirconium 702 Wire is a filamentary material made of high-purity zirconium or zirconium alloy (such as niobium-containing alloy). It has the characteristics of super corrosion resistance, high temperature resistance, high strength, and lightweight. It also has a low neutron absorption cross-section and good biocompatibility. It is suitable for the chemical industry, nuclear industry, aerospace, medical equipment, and other fields, and can produce anti-corrosion components, nuclear reactor auxiliary structures, precision instrument components, and implantable medical components etc.

Zirconium Wire Features

- Exceptional Corrosion Resistance: Demonstrates outstanding tolerance to organic acids, alkaline solutions, seawater, and corrosive media under high-temperature and high-pressure conditions (such as nitric acid and acetic acid), significantly surpassing conventional stainless steel. Ideal for corrosive environments in chemical processing, marine engineering, and similar applications.

- High Strength and Lightweight: With a density of only about 6.5 g/cm³, lower than steel, yet comparable in strength to some high-strength alloys, it reduces equipment weight and is suitable for applications requiring weight reduction, such as aerospace and precision machinery.

- High-Temperature Resistance and Stability: With a melting point of 1852°C, it maintains good mechanical properties and chemical stability at elevated temperatures, making it suitable for high-temperature applications like furnaces and nuclear industries.

- Biocompatibility and Non-Magnetic Properties: In medical applications, zirconium wire offers excellent biocompatibility for medical device components. Its non-magnetic nature makes it ideal for manufacturing magnetic-field-sensitive equipment in electronics and instrumentation.

Dimension

| Grade | ZR702(R60702) |

| Diameter | 0.1-8mm |

| Length | 800-2000mm |

| Density | 6.51g/cm³ |

| Melting Point | 1852℃ |

| Surface | Polishing |

| Standard | ASTM B550 |

| Delivery Time | 20 days |

| Certification | ISO 9001 |

Zirconium 702 Wire Application

- Chemical Industry: Used in the manufacture of reactors, pumps, heat exchangers, valves, agitators, conduits, and container linings resistant to acid and alkali corrosion, benefiting from its excellent corrosion resistance.

- Nuclear Industry: As auxiliary components (such as positioning wires and support wires) for nuclear reactor fuel rod cladding, it utilizes its low neutron absorption cross-section characteristics to reduce interference with nuclear reactions, while also resisting high temperatures, high pressures, and coolant corrosion.

- Aerospace: Used in high-temperature sealing structures for aero-engines and lightweight load-bearing components for spacecraft, its high strength and lightweight advantages make it suitable for extreme flight environments; it can also be used to manufacture conductive wires and connecting wires in precision instruments, ensuring stable signal transmission.

- Electronics Industry: As a getter material, it absorbs residual gases in electro-vacuum components (such as electron tubes, X-ray tubes, and traveling wave tubes), maintaining high vacuum levels and improving device performance and lifespan.

- Medical Industry: Used in the manufacture of implantable medical device components (such as orthopedic fixation wires and minimally invasive surgical instrument assemblies), reducing rejection reactions and providing stable fixation.

- Other special applications: It can be used as heating wire in high-temperature furnaces and electrode wire in vacuum equipment, utilizing its high temperature resistance and low volatility to ensure long-term stable operation; it is also used as crucible support wire in precious metal smelting, adapting to high-temperature smelting environments.

Process

① High-purity zirconium ingots or powder are selected. After forging into billets, they undergo extrusion to form round rod blanks, ensuring high density and uniform composition throughout the blank.

② A multi-pass cold drawing process is employed to draw the zirconium rod blanks into wire of the target diameter. Annealing treatment is interspersed during this process to eliminate work hardening and restore plasticity.

③ Precision straightening equipment corrects wire straightness. The wire is then cut to fixed lengths or coiled into spools as required, ensuring dimensional accuracy.

④ Surface treatment includes acid pickling (removing scale and impurities) and polishing. Premium products undergo additional vacuum annealing to relieve internal stresses, enhancing wire toughness and stability.

⑤ After passing dimensional measurement, mechanical property testing (tensile strength, elongation), and surface defect inspection, qualified products are vacuum-packed for shipment.

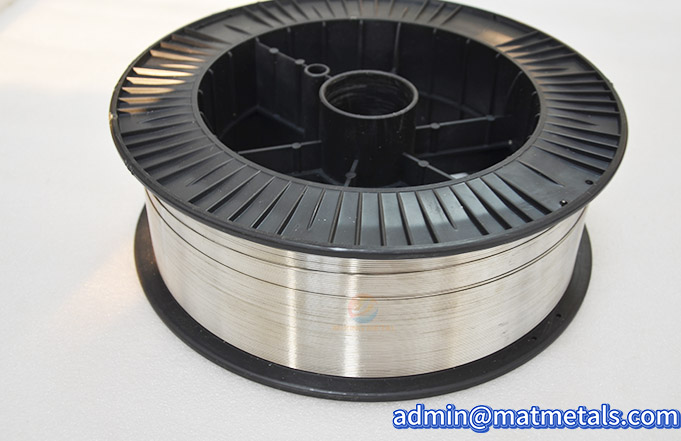

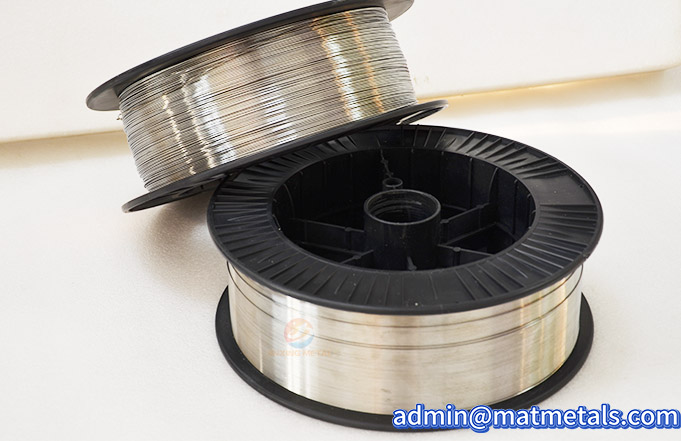

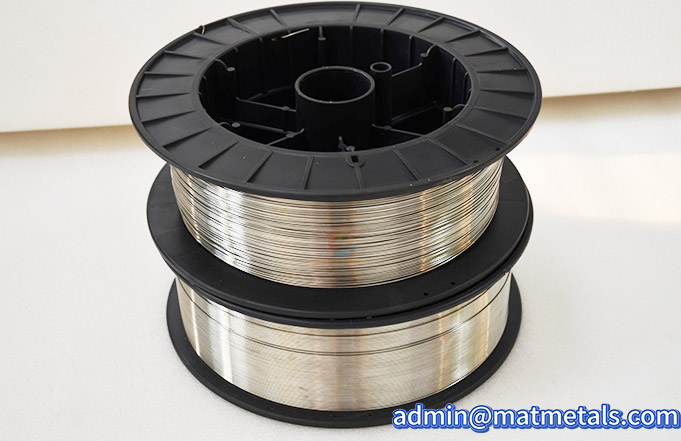

Zirconium 702 Wire Pictures

Please leave your information to get the latest quotation and product catalogue!