Product Description

Overview

Iridium Oxide Sputtering Target is a high-purity thin-film deposition material primarily used in physical vapor deposition (PVD) processes to deposit thin films or coatings through sputtering. Its applications include fuel cells, semiconductors, displays, photovoltaics, aerospace, medical, and new energy fields. Our company can customize production according to customer-provided drawings, offering lower prices than comparable suppliers while ensuring processing quality. For more information, please contact us via email.

Iridium Features

- Iridium has a melting point of approximately 2450–2466°C and a boiling point of approximately 4130°C. It maintains excellent mechanical properties and physical stability at elevated temperatures (such as above 1600°C), making it suitable for coating processes under extreme conditions.

- Iridium exhibits exceptional resistance to strong acids, strong alkalis, molten reagents, and high-temperature silicates. It is resistant to oxidation in atmospheric environments and possesses highly stable chemical properties. This enables thin-film coatings to significantly enhance the corrosion resistance and wear resistance of substrates.

- With a density of approximately 22.56 g/cm³ and a Mohs hardness of 6.5, iridium's high density and hardness characteristics allow it to produce uniform films during sputtering processes. It is suitable for applications such as wear-resistant coatings and semiconductor production.

- Iridium exhibits excellent high-temperature oxidation resistance and thermoelectric properties, making it suitable for manufacturing thermocouples, serving as a material for radioactive heat source containers, or functioning as an electrochromic material (such as anodised iridium films).

Iridium Target Dimension

|

Material |

Iridium oxide |

|

Purity |

99.95%,99.9%, 99.99%, 99.999% |

|

Diameter |

50.8mm |

|

Thickness |

1mm |

|

Density |

11.7g/cm3 |

|

Shape |

Round |

|

Surface |

Alkaline Cleaning, Polished, Bright |

|

Delivery Time |

15-25 days |

|

Certification |

ISO 9001 |

Application

- Iridium oxide sputtering targets are employed in the production of thin-film coatings for semiconductor devices, integrated circuits, and electronic components, enhancing conductivity and durability. They are frequently utilised in high-frequency electronics and microelectronics applications.

- In proton exchange membrane fuel cells (PEMFC), they serve as catalyst layers or electrode coatings, facilitating oxygen reduction and oxygen evolution reactions to boost cell efficiency and longevity.

- They are employed in depositing optical films to enhance reflectivity, oxidation resistance, and optical performance in displays, LEDs, and solar cells.

- Surface coating for architectural glass, automotive glazing and decorative items, providing scratch resistance, corrosion protection and aesthetic effects such as enhanced gloss and colour.

- Deposition of hard coatings on tools, jewellery, and industrial components for aerospace, automotive, and high-temperature equipment, improving wear resistance and oxidation resistance.

- Used in laboratory thin-film deposition experiments and specialised applications requiring high stability and purity, such as alloy hardeners in high-temperature environments.

Process

① Ion exchange chromatography is used to remove impurities such as iron and nickel, achieving an iridium oxide purity of over 99.99%, meeting the requirements for semiconductor-grade applications.

② Iridium oxide powder is loaded into a mold, subjected to pressure and high-temperature sintering, increasing the target density through interparticle plastic deformation and atomic diffusion.

③ High-precision machining is achieved using a CNC grinding machine, eliminating stress deformation during sintering and controlling the target thickness tolerance within ±0.05mm.

④ Surface activation and polishing remove surface contaminants, increase active sites, improve surface finish, and ensure sputtering uniformity.

⑤ Multi-dimensional quality control, such as component analysis, performance testing, and dimensional accuracy checks, ensures the quality of the final product.

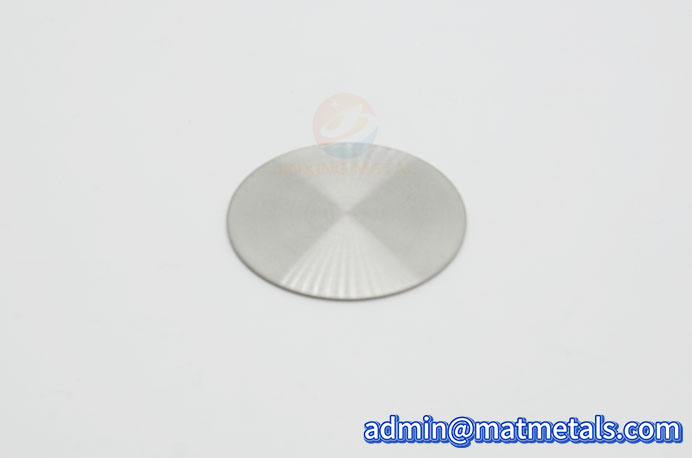

Iridium Oxide Sputtering Target Pictures

Packing

Please leave your information to get the latest quotation and product catalogue!