Product Description

Overview

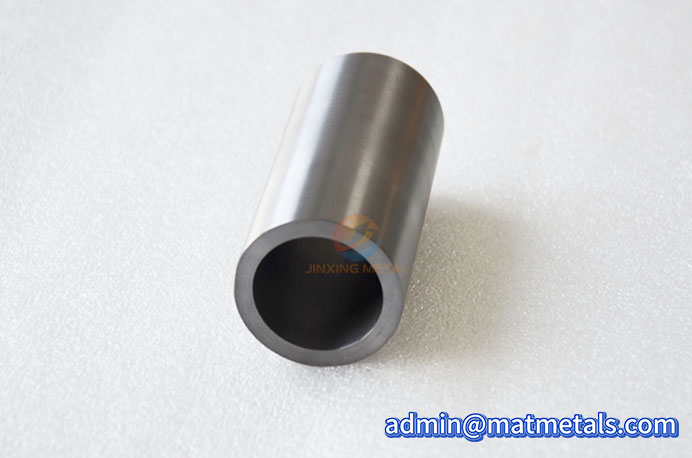

Tantalum Pipe Ta Tube, a pipe made of the rare metal tantalum, occupies an important position in the fields of core chemical equipment, high-end electronic devices, medical implants, aerospace, etc., with its triple property combination of "corrosion resistance + high temperature resistance + biocompatibility".

Advantages

- Tantalum has strong corrosion resistance to almost all inorganic acids (such as sulfuric acid, hydrochloric acid, nitric acid, aqua regia), organic acids, and strong alkaline solutions at room temperature.

- The melting point of tantalum is as high as 2996℃, second only to tungsten and rhenium among refractory metals, and it can still maintain good strength and oxidation resistance at high temperatures.

- Tantalum has excellent conductivity (conductivity of about 24% IACS), and its resistance stability is strong in high-frequency and high-temperature environments, and it is not easily affected by external interference.

- It has good toughness and fatigue resistance. Through cold processing and annealing, it can be made into thin-walled tubes, capillaries, and other precision structures.

- Tantalum is non-toxic and has no rejection reaction to human tissues, and its porous structure can promote the growth of bone cells and has bone conductivity.

Application

Tantalum Pipe Ta Tube can not be replaced in extreme working conditions with strong corrosion, high temperature, and high reliability requirements. Although the cost is high, it is mostly used in high-end fields such as aerospace and semiconductors.

- Chemical industry: strong acid, strong alkali, and fluorine/chloride chemical processes, such as reactor lining, heat exchangers, and corrosive medium pipelines.

- Electron and semiconductor: high temperature electron tube, vacuum device (radar tube, electron beam evaporation electrode), sputtering target carrier in semiconductor manufacturing, wafer annealing furnace tube.

- Aerospace: rocket engine nozzles, combustion chamber components (resistant to high-temperature gas corrosion), radiation-resistant pipes.

- Biomedical: Orthopedic implants (bone nails, spinal fixators), cardiovascular stents, dental implants, and other medical devices.

Dimension

|

Grade |

Ta1,Ta2,TaW2.5,TaW7.5,TaW10,TaNb3,TaNb20 |

|

Purity |

≥99.95% |

|

Diameter |

φ6mm-600mm |

|

Wall Thickness |

0.1-50mm |

|

Length |

50mm-6000 mm |

|

Density |

16.68g/cm3 |

| Hardness |

100-220HV |

|

Standard |

ASTM B521, ASTM F560, GB/T 8182 |

|

Certification |

ISO 9001 |

Process

① Extract high-purity tantalum materials from raw materials to ensure subsequent processing.

② Use cold isostatic pressing or hot isostatic pressing for uniform pressing to improve density.

③ Perform multiple rolling passes on the rolling mill to reduce wall thickness and improve organization

④ Drawing can be used for seamless pipes, and the TIG process can be used for large-size welded pipes.

⑤ Annealing treatment and surface finishing, with high surface finish and flatness.

Pictures

Please leave your information to get the latest quotation and product catalogue!