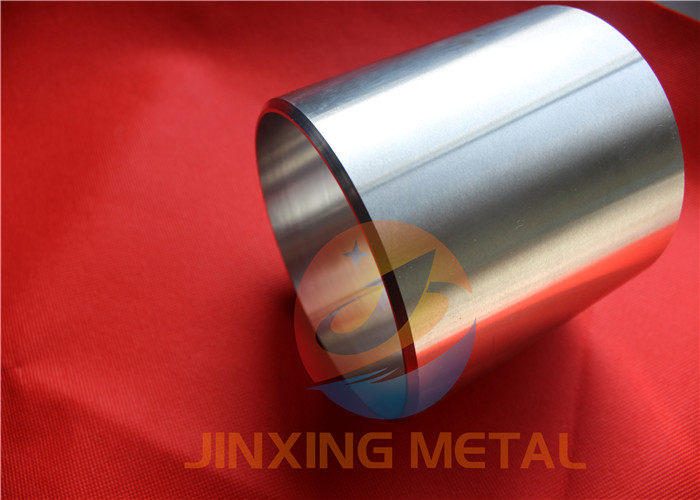

Product Description

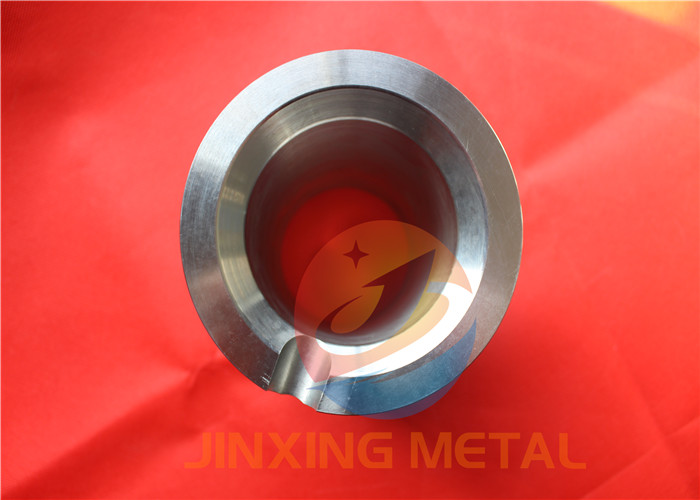

Cobalt Chromium Tungsten Alloy bushing of Introdution

Cobalt Chromium Tungsten Alloy bushing and sleeve are the advantaged products for us , we have produced more than thousands specifications and all of them are produced upon customer’s drawing .

There are two kind of process in our company , PM products and castings . They have each advantages and stellite alloy are applied in the industries as nuclear, petrochemistry, battery , food etc. Regular products include valve balls, seat , bearings , sleeves, pump parts pears , gears , batteries dies , nozzles and cutters .

Cobalt Chromium Tungsten Alloy bushing of Product Features

1. High temperature resistance

The strength keeps stable up to 800℃ and it can even momentarily used at 1200℃.

2. Wear resistance

Due mainly to the unique inherent characteristics of the hard carbide phase dispersed in a

CoCr alloy matrix, it has exceptional wear and galling resistance.

3. Corrosion resistance

This exellent and lovely property allows this kind of material parts to be used in oil&gas, slurry,

acid liquid and any other mediums.

Cobalt Chromium Tungsten Alloy bushing Typical Application

Materail JX-Co3, JX-Co6, JX-Co20

JX-3 equal to the material stellite 3 ( stellite brand belong to Kennametal)

JX-6 equal to the material stellite 6( stellite brand belong to Kennametal)

JX-3 equal to the material stellite 3

JX-6 equal to the material stellite 6

Reference : Stellite3, stellite6, stellite20 ( stellite brand belong to Kennametal)

|

Material Choose |

Typical Application |

Process |

|

JX- 6 |

Steam and chemical valve seat , oil and gas pump sleeve, ,butterfly valve bushing ,hot-dip galvanized production line used bushing etc. |

Powder metallurgy & investment casting |

|

JX-3 |

Pump sleeve ,rotary ring , valve seats |

Powder metallurgy & investment casting |

|

JX-12 |

Extrusion die , hot impact die and saw teeth |

Powder metallurgy |

|

JX-100 |

Extrusion die , hot-impact die and saw teeth |

Powder metallurgy |

|

JX-20 |

Pump sleeves , rotary rings , bearing sleeves , valve balls |

Powder metallurgy |

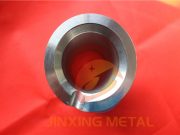

Details of Cobalt Chromium Tungsten Alloy bushing and sleeve

|

Material : |

Stellite –Grade 3.6.12 |

|

Process : |

Powder Metallurgy , it is short for PM and investment casting |

|

Hardness: |

38-50HRC |

|

Density : |

8.4 g/cm ³ |

|

Size : |

Diameter 8-500mm and maxium length 500mm |

|

Properties : |

Wear and corrosion resistance, high temperature resistance |

|

Application : |

Oil and gas equipment such as pump , valve , other environment need wear and corrosion resistance parts |

|

Instructions : |

Drawing made upon cutomers request |

|

Tolerance control : |

turning or grinding surface , tolerance upon drawing |

|

Production lead time |

Normal order 15-25 days |

|

Production capacity : |

20,000pcs one month. |

|

Package : |

carton or wooden case , pallet for export |

Please leave your information to get the latest quotation and product catalogue!